GAS SHIELDED METAL ARC WELDING (GMAW)

COPPER COATED C-Mn STEEL GMAW FILLER WIRE FOR

600 TO 700 MPA TENSILE STRENGTH STEEL

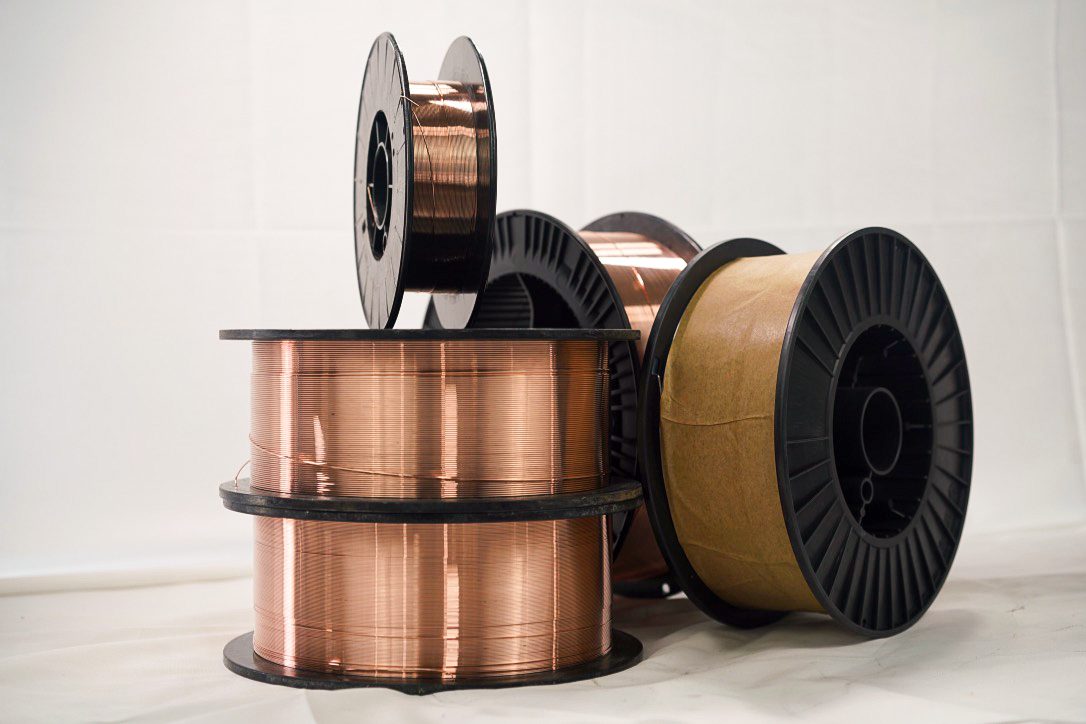

A MIG/MAG wire is a type of welding wire used for welding. MIG stands for metal inert gas(ARGON AND HELIUM), MAG stands for metal active gas (CO2 . Welds are typically protected from oxygen in the air by CO2 for ER80S-D2 and a mixture of argon/1-5 % O2 for ER90S-D2.

Most commonly, MIG/MAG wires are used to weld thin pieces of metal together. Additionally, they may be used to fill gaps between metal pieces by inserting filler wire between them.

MIG/MAG welding is used to join metal pieces. A clamp is used to secure the pieces, The wire is inserted into the welding gun, and turn it on. A constant feed and trigger action should then be set up. It will maintain a consistent weld bead along the joint line.

The following industries commonly use MIG /MAG wires:

It is used in the automotive industry to weld sheets and panels of metal together. The construction industry uses it to weld steel structures together.

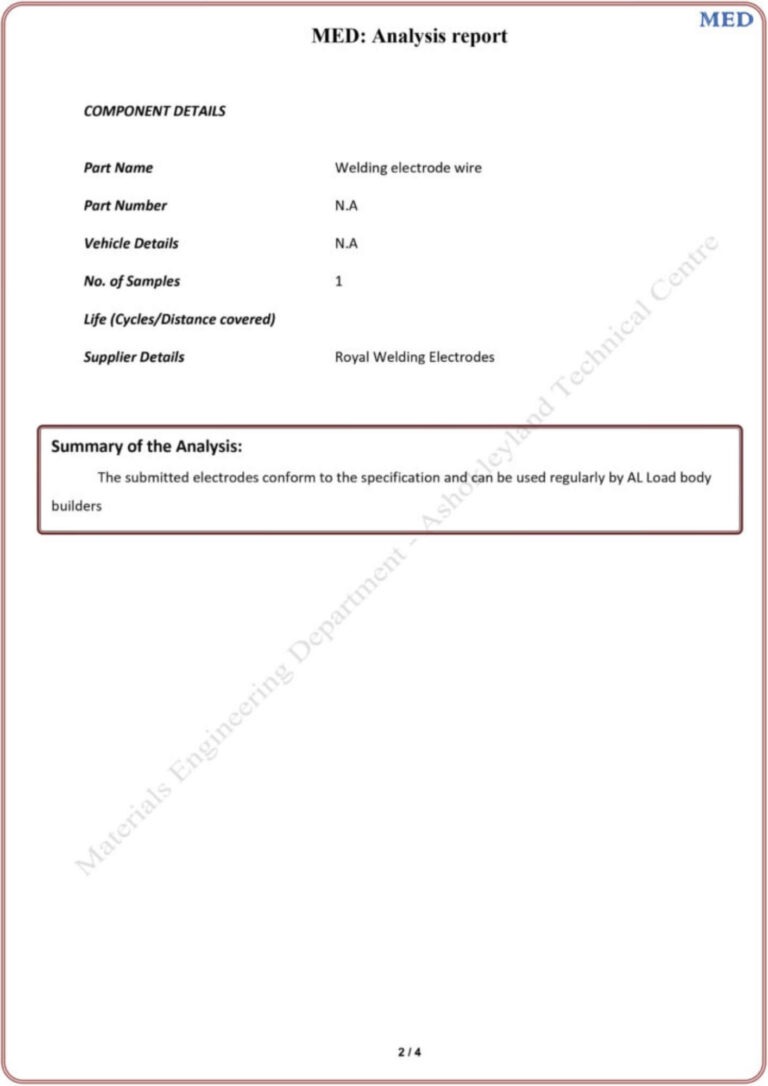

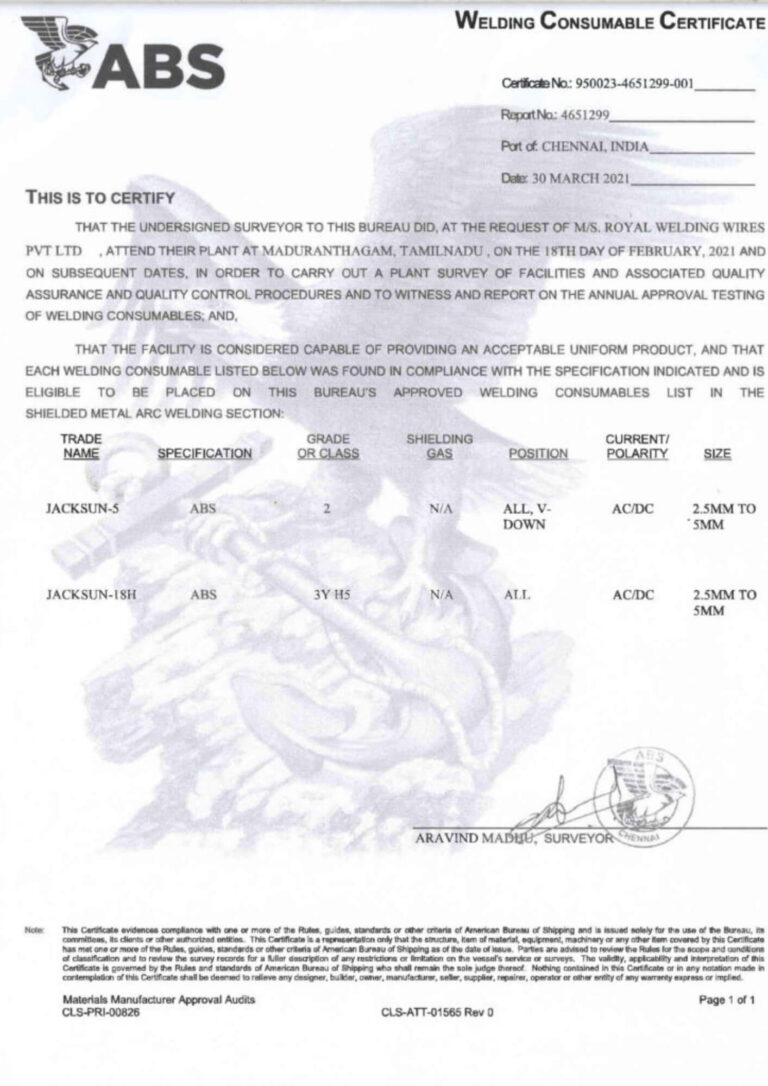

Jacksun 80S-D2 , Jacksun 90S- D2 filler wires are widely used for welding steel products with a tensile strength of 600-700 MPa. Our process of coating the wire with copper enables it to assume a perfect shape during welding, resulting in a high-quality weld that is reliable and durable.

Jacksun Low alloy Steel MIG/MAG Wire provides a high level of de-oxidizers so your weld is defect-free. Also suitable for single and multiple pass welding, it is an affordable and versatile filler wire that will meet the needs of all welders.

| ELEMENTS | C % | Mn % | Si % | P % | S % | Ni % | Mo % | Cu* % |

|---|---|---|---|---|---|---|---|---|

| SPECIFICATION | 0.07 - 0.12 | 1.60 - 2.10 | 0.50 - 0.80 | 0.025 MAX | 0.025 MAX | 0.15 MAX | 0.40 - 0.60 | 0.50 MAX |

| TYPICAL VALUE | 0.07 | 1.650 | 0.550 | 0.016 | 0.010 | 0.010 | 0.45 | 0.20 |

* INCLUDING FINISHED COPPER COATING %

| PROPERTIES | SHIELDING GAS | TENSILE STRENGTH, Mpa |

Yield Strength at 0.2 % offset >Mpa |

ELONGATION % | CVN Impact at -30⁰ C , J |

|---|---|---|---|---|---|

| SPECIFICATION | 100 % CO2 | 550 min | 470 min | 17 min | 27 min |

| SIZE ( mm ) | VOLTAGE, V | AMPS | WEIGHT (kg) / SPOOL |

|---|---|---|---|

| 1.20 | 20 - 34 | 120 - 400 | 15 |

| 1.60 | 24 - 36 | 150 - 450 | 15 |

NIL

| ELEMENTS | C % | Mn % | Si % | P % | S % | Ni % | Mo % | Cu* % |

|---|---|---|---|---|---|---|---|---|

| SPECIFICATION | 0.07 - 0.12 | 1.60 - 2.10 | 0.50 - 0.80 | 0.025 MAX | 0.025 MAX | 0.15 MAX | 0.40 - 0.60 | 0.50 MAX |

| TYPICAL VALUE | 0.07 | 1.650 | 0.550 | 0.016 | 0.010 | 0.010 | 0.45 | 0.20 |

* INCLUDING FINISHED COPPER COATING %

| PROPERTIES | SHIELDING GAS | TENSILE STRENGTH, Mpa |

Yield Strength at 0.2 % offset >Mpa |

ELONGATION % | CVN Impact at -30⁰ C , J |

|---|---|---|---|---|---|

| SPECIFICATION | AR / 1-5 % O2 100 % CO₂ |

620 min | 540 min | 17 min | 27 min |

| Ø, mm | 1.20 mm | 1.60 mm |

|---|---|---|

| Voltage, V | 20 – 34 | 24 – 36 |

| Amperage, A | 120 - 400 | 150 - 450 |

| Kg/Spool | 15 | 15 |

NIL

We’re about innovation, performance and delivering the best for our customers with every product we offer.