LOW HYDROGEN WELDING ELECTRODE FOR MILD & MEDIUM TENSILE STEELS

SHIELDED METAL ARC WELDING (SMAW)

AWS / SFA 5.1 E 7018 & AWS / SFA 5.1 E 7018-1

IS 814 EB 5426 H3JX & EB 5629 H3JX

Welding electrodes are consumable metal products that are used in the process of welding. They provide a pool of molten metal to be used for welding. Welding electrodes are used to create heat and energy to weld two or more pieces of metal together.

The metal pieces come in various shapes and sizes depending on what they will be used for. The diameter of rod is determined by the thickness of the metal to be welded, and the length is determined by how long you want your weld to be.

Low-hydrogen welding electrodes are a type of welding electrode that is used for the purpose of joining two pieces of metal together.

They are made up of wire coated with flux. The welding process starts with the striking of an arc between the electrode and metal that is being welded.

Low-hydrogen welding electrodes are important because they provide excellent arc stability and low spatter, making them ideal for use in confined spaces such as shipyards and warehouses where flammable materials might be present.

These electrodes can be used on all positions in the shop, including flat, horizontal and vertical down hand positions.

| ELEMENTS | C % | Mn % | Si % | P % | S % | Ni % | Cr % | Mo % | V % |

|---|---|---|---|---|---|---|---|---|---|

| SPECIFICATION | 0.15 MAX | 1.60 MAX | 0.75 MAX | 0.035 MAX | 0.035 MAX | 0.30 MAX | 0.20 MAX | 0.30 MAX | 0.08 MAX |

| TYPICAL VALUE | 0.08 - 0.10 | 0.30 - 1.60 | 0.30- 0.75 | 0.020 | 0.020 | 0.010 | 0.010 | 0.010 | 0.010 |

| PROPERTIES | TENSILE STRENGTH, Mpa |

Yield Strength at 0.2 % offset >Mpa |

ELONGATION % | CVN Impact at -30⁰ C , J |

|---|---|---|---|---|

| SPECIFICATION | 490 min | 400 min | 22 min | 27 min |

| TYPICAL VALUE | 550 - 610 | 490 - 530 | 24 - 28 | 50 -70 |

| SIZE X LENGTH | AMPS | PCS / CARTON | CARTON / BOX | APPROX. WT OF 1000 PCS, kg |

|---|---|---|---|---|

| 2.50 X 350 | 60 - 100 | 150 | 4 | 15.5 |

| 3.15 X 350 | 100 - 140 | 120 | 4 | 21.5 |

| 4.00 X 450 | 140 - 190 | 80 | 4 | 22 |

| 5.00 X 450 | 190 - 250 | 44 | 4 | 22 |

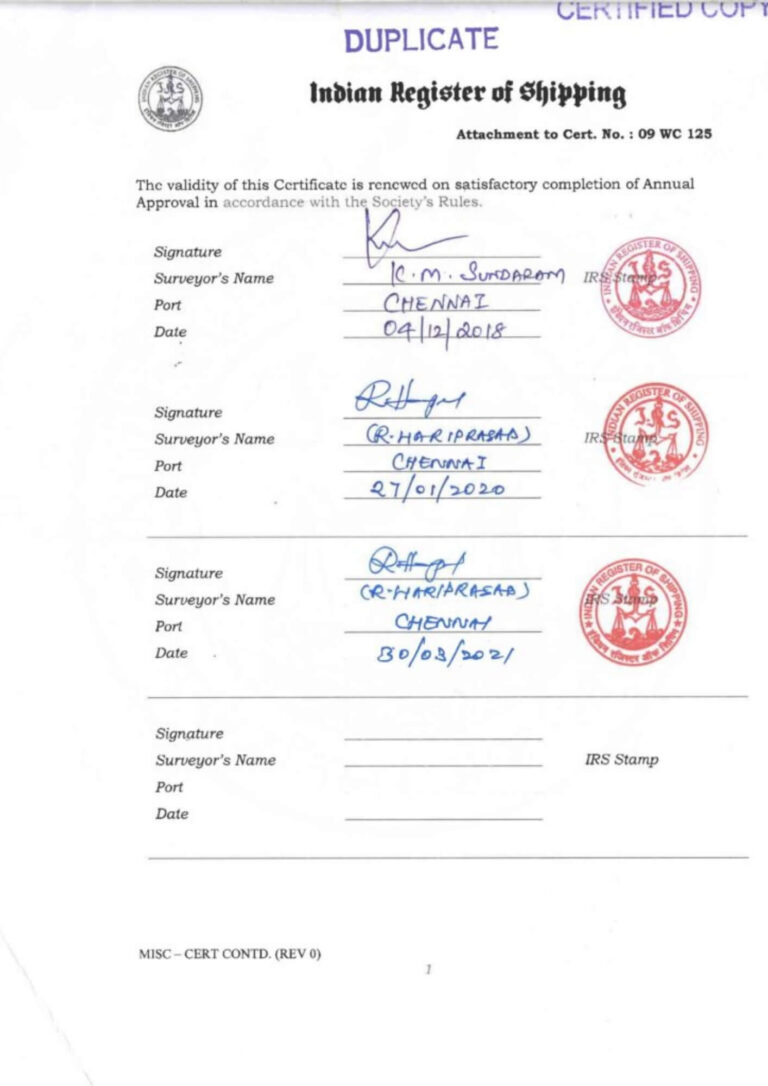

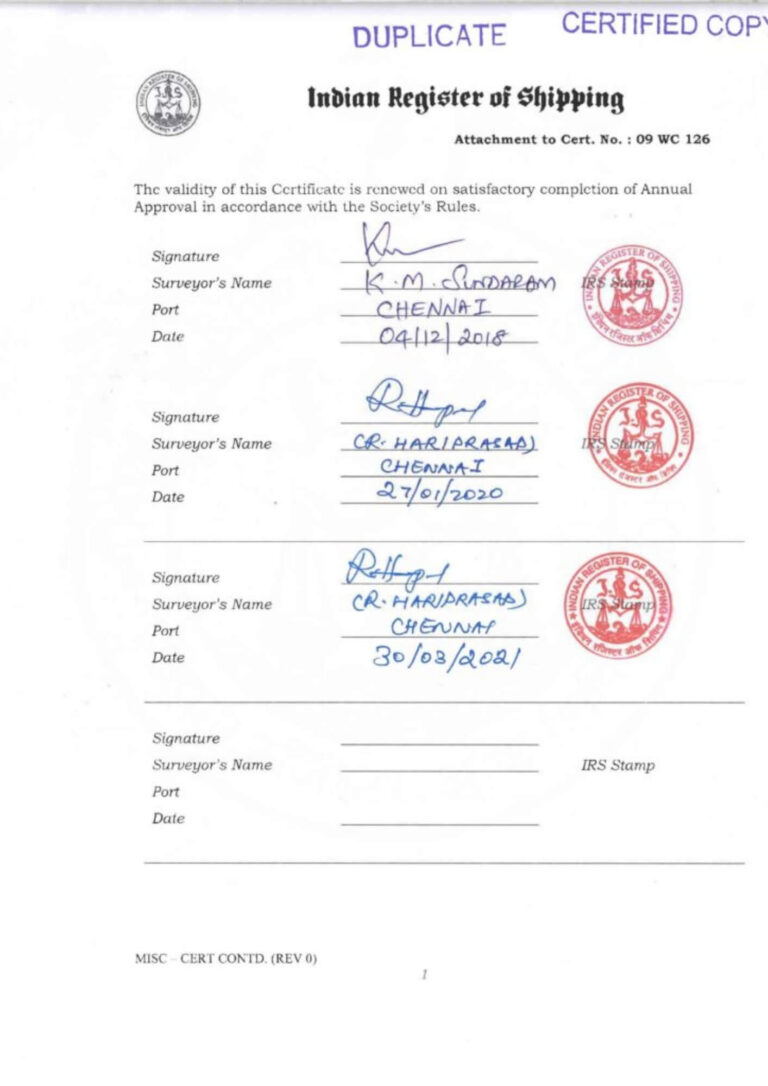

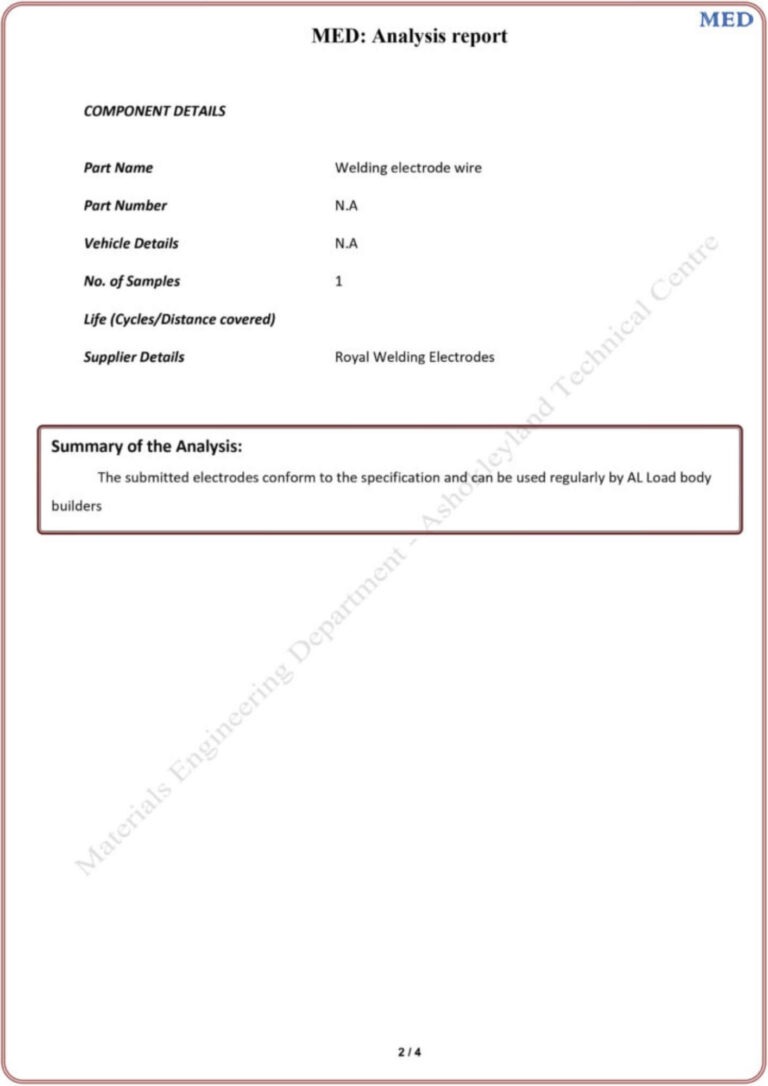

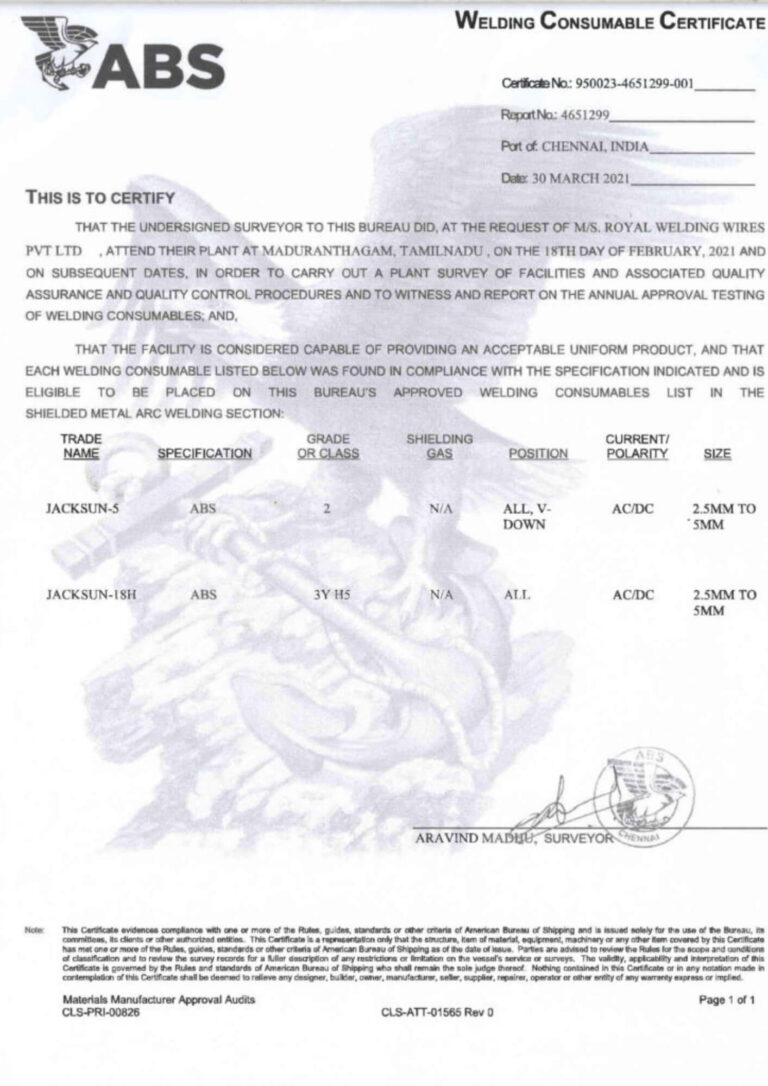

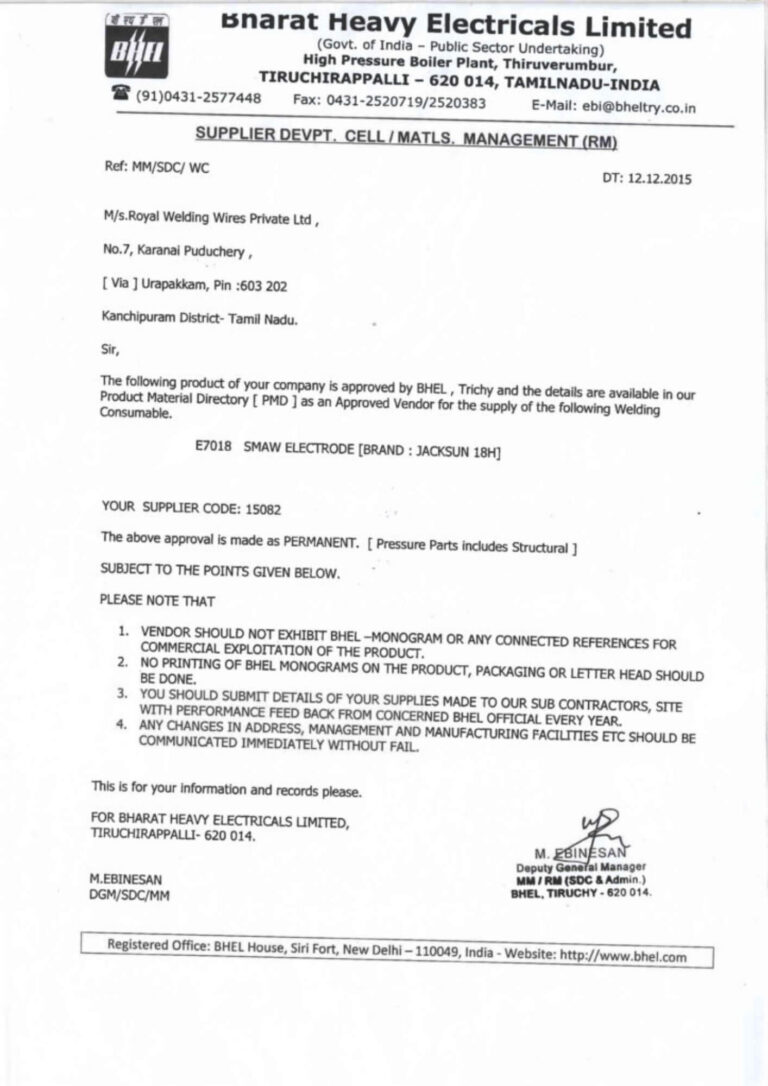

CE/BIS/IBR/BHEL/Cethar Vessels/IRS Gr.3YHH/ABS Gr.3YH5

| ELEMENTS | C % | Mn % | Si % | P % | S % | Ni % | Cr % | Mo % | V % |

|---|---|---|---|---|---|---|---|---|---|

| SPECIFICATION | 0.15 MAX | 1.60 MAX | 0.75 MAX | 0.035 MAX | 0.035 MAX | 0.30 MAX | 0.20 MAX | 0.30 MAX | 0.08 MAX |

| TYPICAL VALUE | 0.08 - 0.10 | 0.30 - 1.60 | 0.30- 0.75 | 0.020 | 0.020 | 0.010 | 0.010 | 0.010 | 0.010 |

| PROPERTIES | TENSILE STRENGTH, Mpa |

Yield Strength at 0.2 % offset >Mpa |

ELONGATION % | CVN Impact at -30⁰ C , J |

|---|---|---|---|---|

| SPECIFICATION | 490 min | 400 min | 24 min | 27 min |

| TYPICAL VALUE | 550 - 610 | 490 - 530 | 24 - 34 | 50 -80 |

| SIZE X LENGTH | AMPS | PCS / CARTON | CARTON / BOX | APPROX. WT OF 1000 PCS, kg |

|---|---|---|---|---|

| 2.50 X 350 | 60 - 100 | 150 | 4 | 15.5 |

| 3.15 X 350 | 100 - 140 | 120 | 4 | 21.5 |

| 4.00 X 450 | 140 - 190 | 80 | 4 | 22 |

| 5.00 X 450 | 190 - 250 | 44 | 4 | 22 |

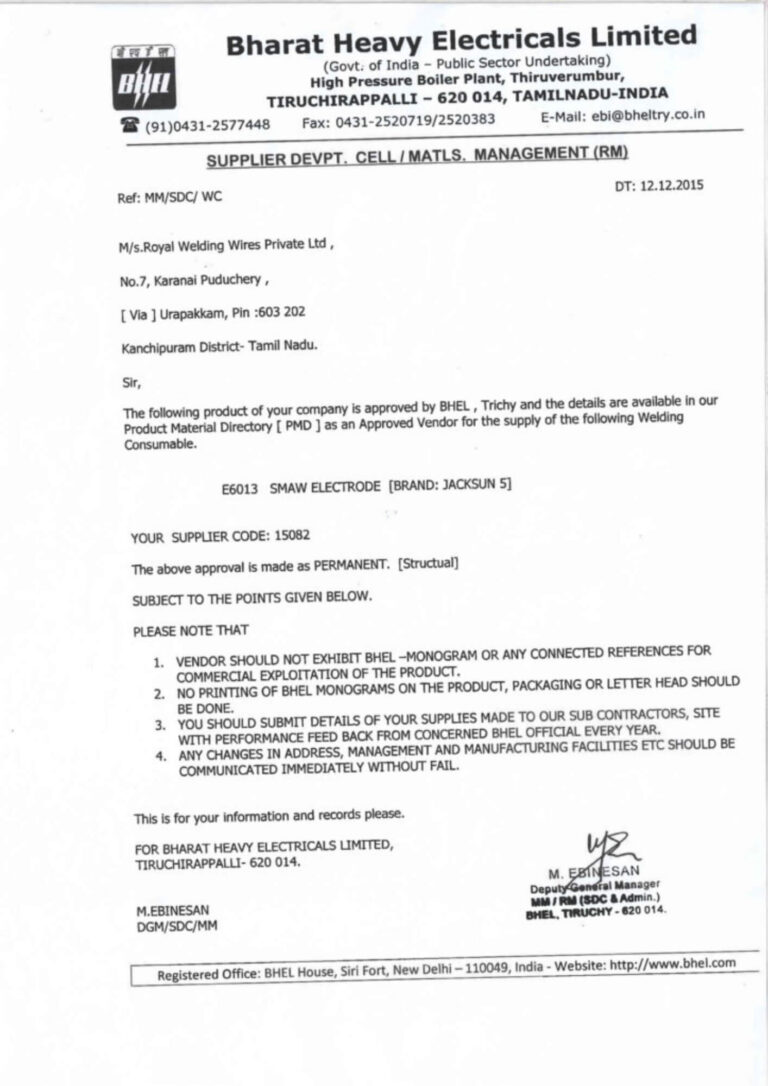

CE / IBR

We’re about innovation, performance and delivering the best for our customers with every product we offer.