MIG welding is a popular method for metalworking because it is relatively easy to learn and use, produces good-quality welds, and is relatively affordable.

MIG welding joins thin metal sheets, most commonly in the automotive and aerospace industries.

Introduction

MIG welding is metal welding that uses an electric arc to melt and join metal pieces together. The heat from the welding process melts the metal, which is then drawn into the electrode by capillary action.

MIG Welding is most commonly used for fabrication and repairs on aluminum and steel.

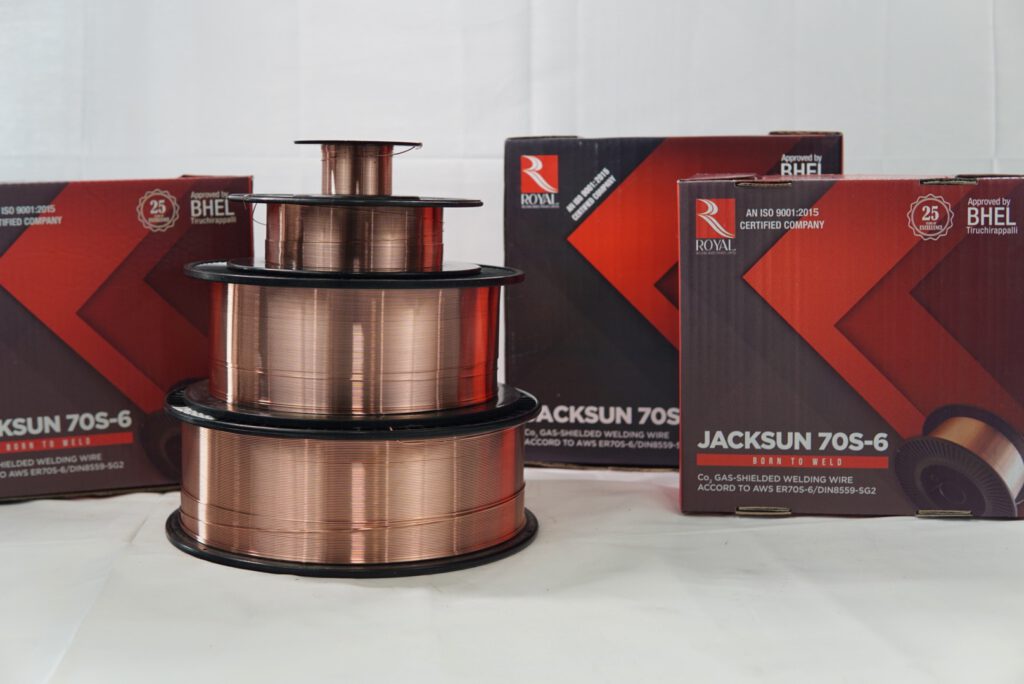

Mig wire is a thin, aluminum-coated wire fed through the weld zone and used to hold the electrode in position. By controlling the strength and duration of the electric arc, MIG welders can create a variety of welds with different properties.

What happens when you use MIG wire without gas?

When using MIG wire without gas, the electrical current travels through the metal instead of being heated by the gas.

This is why MIG wire is often used in welding and cutting applications where a consistent, narrow beam is needed. Additionally, MIG welds are less likely to spatter than TIG welds.

What is MIG wire used for?

MIG wire is a welding wire specifically designed for use with MIG welders. It is made from a combination of copper and nickel, which makes it strong and flexible.

MIG wire is used to join metal pieces together, and it is also often used to create parts that are too large or too delicate to be welded using other types of welding techniques.

Transform your welding projects with the versatility of MIG wire. Discover the numerous applications and benefits of this essential welding material. Upgrade your equipment and achieve superior results with every project. Click here to learn more and find the right MIG wire for your needs.

Can you use MIG wire without gas?

MIG wire is a welding wire used in industrial and construction applications. It is composed of tungsten and molybdenum and is heated to a high temperature to create a gas-less arc.

MIG welding is famous for its ability to join metals quickly and with little heat distortion.

Which is more robust, ARC or MIG?

MIG wire is a welding wire made of a wire core covered in a layer of flux. MIG welds are faster than ARC welding but less heat-resistant than ARC welds. MIG welding is commonly used for metals that cannot be welded using an arc welder, such as stainless steel.

What is MIG stands for?

MIG wire is a type of welding wire used in arc welding. It is made of several thin alternating layers of steel and brass. When Welding with MIG, the electrode (the weld) is placed near the end of the wire, where it touches both pieces being joined. The gas flow is turned up to full power, and the weld is made. When the weld is complete, the MIG wire can be quickly drawn out of the joint, leaving a clean and smooth finish.

Does MIG use Volts or amps?

MIG welding is a type of welding that uses a welder’s gas called MIG (mild-gaseous-inert-gas) to weld metals. The welds are usually much more robust than those made with other types of welding because the heat from the arc causes the metal to flow together rather than melt.

The most common use for MIG welding is in repairing pipelines and other equipment. MIG welders are also used in manufacturing and construction.

Conclusion

MIG welding is a viral process for joining metals, and it’s used in everything from airplane construction to car manufacturing.

In MIG welding, a wire feeder melts the weld material at the tip of an electrode into a liquid form. Then, the molten weld material is forced through a hole in the workpiece by an electric current and deposited on the other side.