GAS SHIELDED METAL ARC WELDING ( GMAW )

COPPER COATED C-Mn STEEL GMAW FILLER WIRE FOR

500 MPA TENSILE STRENGTH STEEL

MIG/MAG welding wire is used in welding. There is a difference between MIG and MAG: MIG stands for metal inert gas (ARGON, HELIUM), and MAG stands for metal active gas (CO2).

MIG/MAG wires are most commonly employed to weld thin pieces of metal together. They are used to fill gaps between two pieces of metal by depositing filler wire into them.

To join metal pieces, welders work with MIG/MAG. As the pieces are clamped together, the wire is inserted into the gun of a welding machine. This should be followed by a constant feed and trigger action. This will maintain a consistent weld line along the joint.

The welder has control over how much heat is applied to each area by using a regulator available in the welding machine.

Metal sheets and panels are usually joined with MIG/MAG wires in the automotive industry. Steel structures are welded with MIG/MAG wires in the construction industry. Copper and aluminium cables are welded with MIG/MAG wires in the electrical industry. The aerospace industry uses MIG/MAG to join parts of planes. These include wings and fuselages.

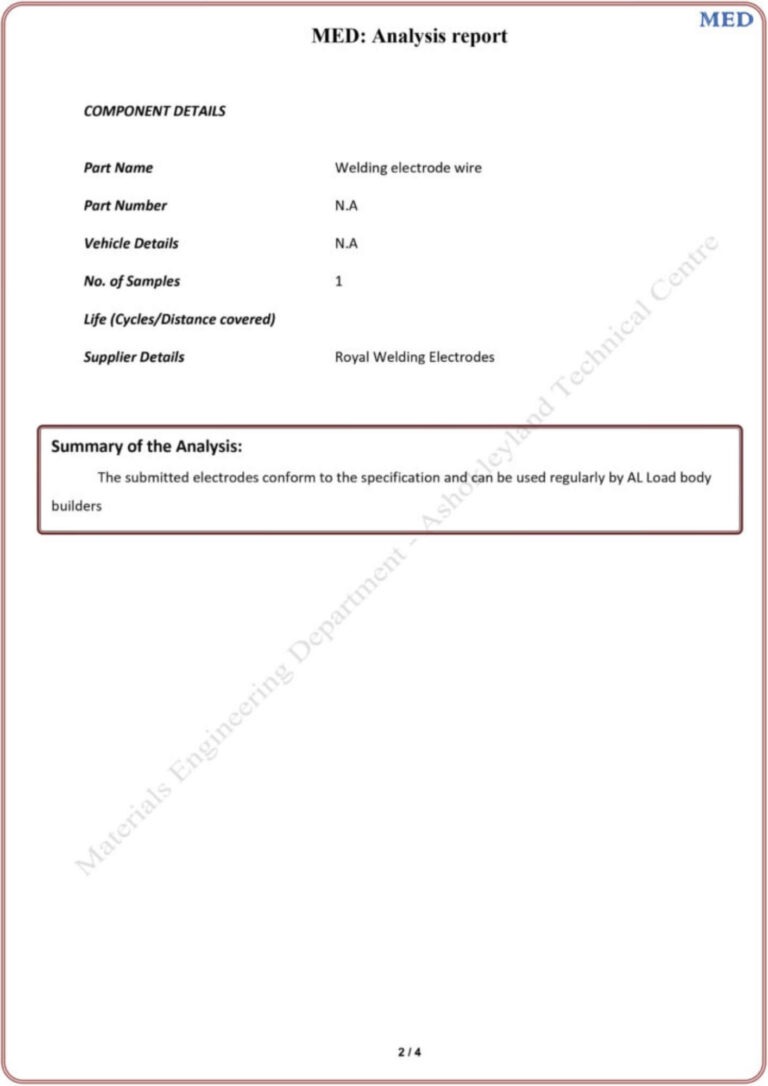

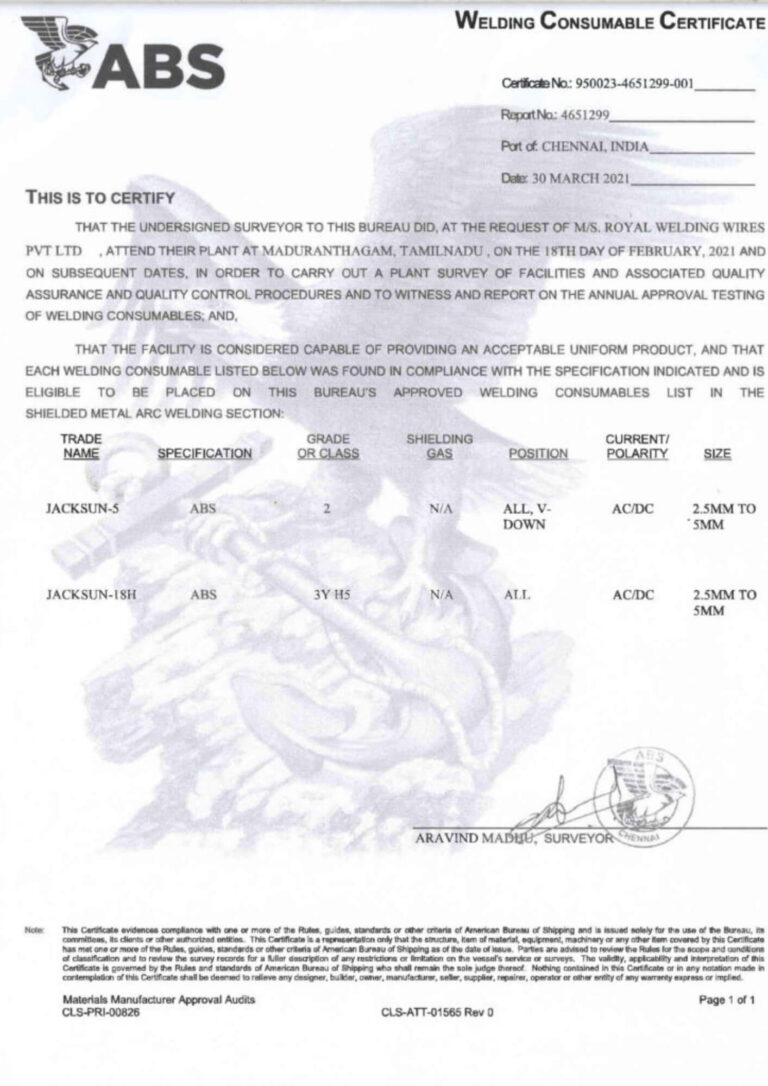

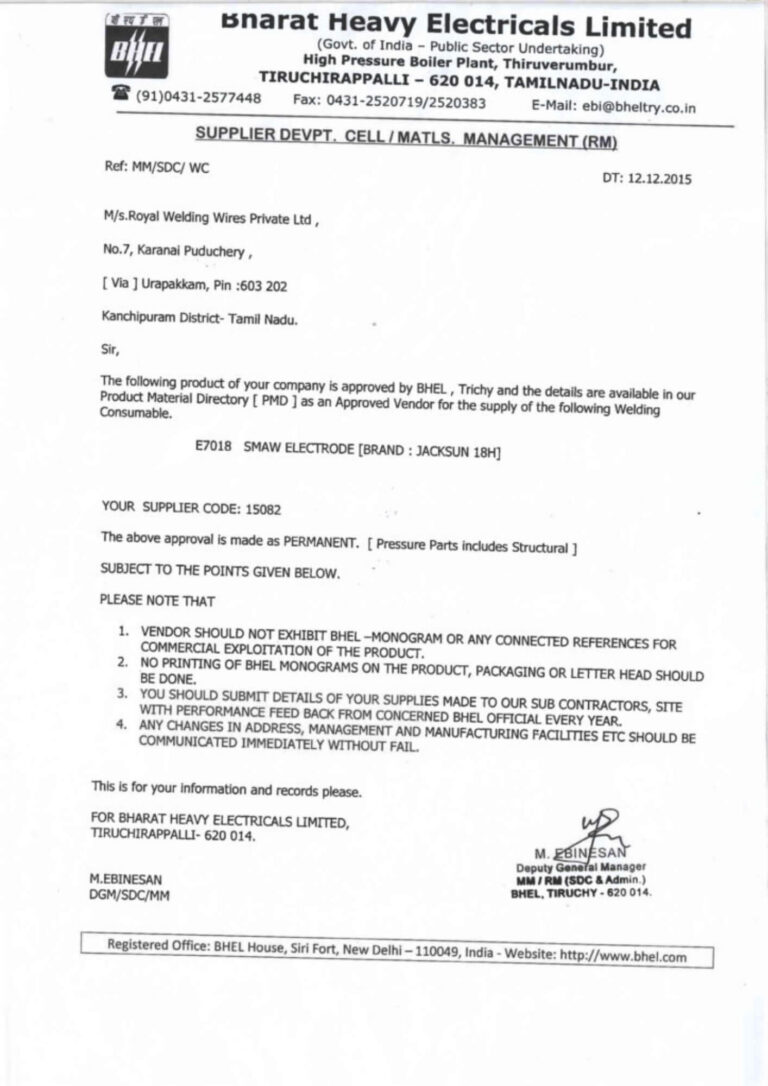

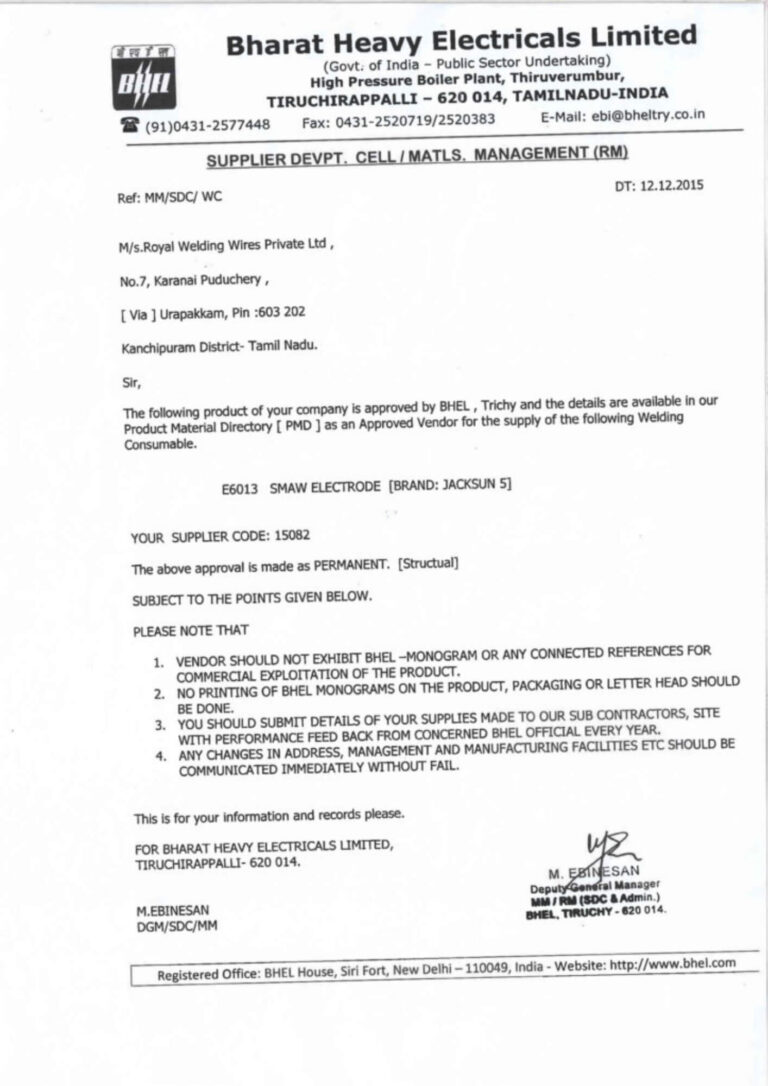

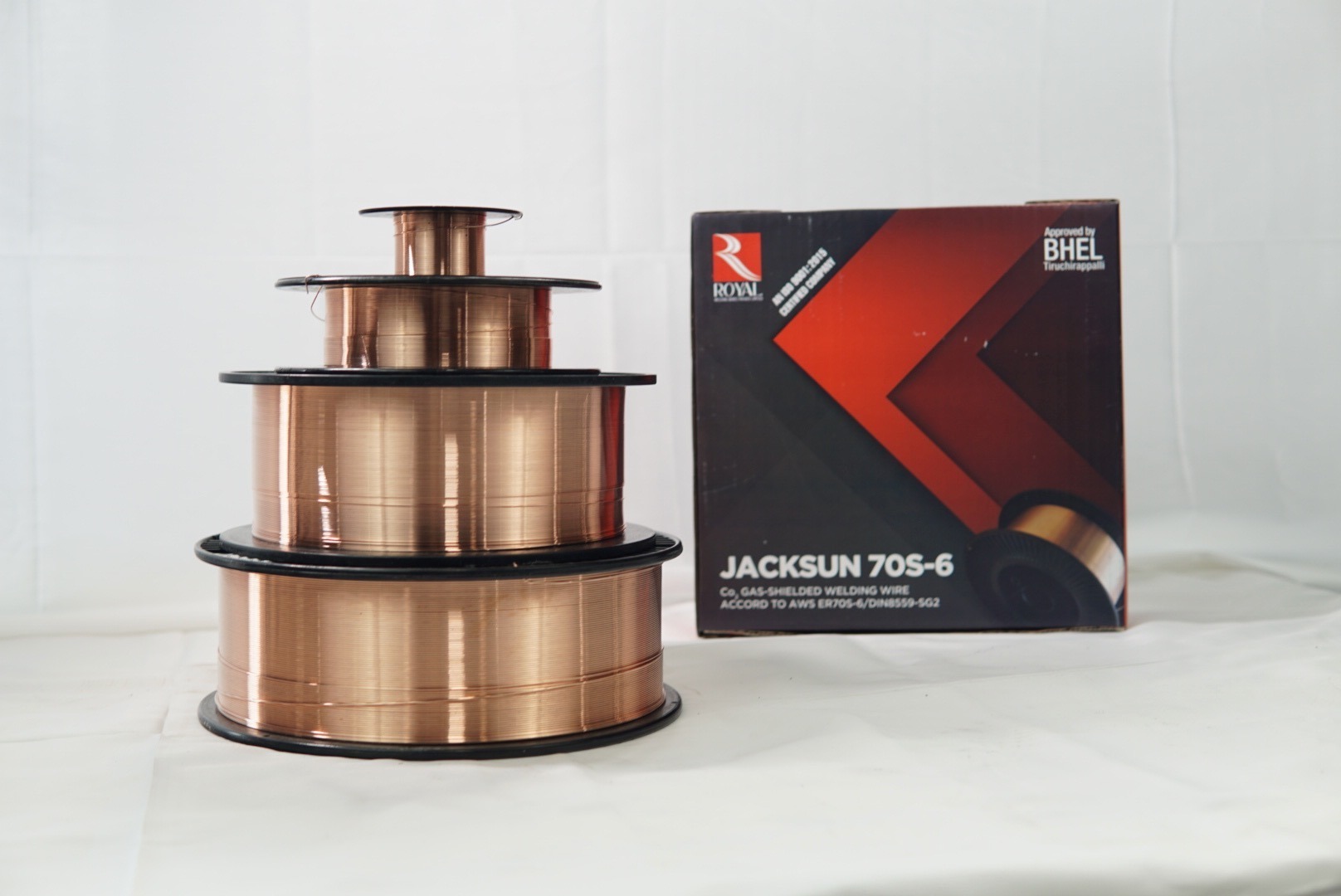

Jacksun is a world-leading producer of high-quality welding consumables, specializing in the production of copper-coated wire for MIG/MAG welding.

JACKSUN ER 70S is a high quality, low alloy steel wire with a copper coating for use in all position welding. With excellent weldability and mechanical properties, it is the perfect wire for any task.

| ELEMENTS | C % | Mn % | Si % | P % | S % | Ni % | Cr % | Mo % | V % | Cu* % |

|---|---|---|---|---|---|---|---|---|---|---|

| SPECIFICATION | 0.06 - 0.15 | 0.90 - 1.40 | 0.45 - 0.75 | 0.025 MAX | 0.035 MAX | 0.15 MAX | 0.15 MAX | 0.15 MAX | 0.03 MAX | 0.50 MAX |

| TYPICAL VALUE | 0.07 | 0.99 | 0.50 | 0.010 | 0.010 | 0.010 | 0.010 | 0.010 | 0.010 | 0.20 |

| SHIELDING GAS | TENSILE STRENGTH, Mpa |

Yield Strength at 0.2 % offset >Mpa |

ELONGATION % | CVN Impact at -20⁰ C , J | |

|---|---|---|---|---|---|

| SPECIFICATION | 100 % CO2 | 480 min | 400 min | 22 min | 27 min |

| AR + (5 - 20)% CO2 | 530 - 680 | 460 min | 22 - 35 | 27 min |

| SIZE ( mm ) | VOLTAGE, V | AMPS | WEIGHT (kg) / SPOOL | MIG/ MAG DRUM, kg |

|---|---|---|---|---|

| 0.80 | 17 - 27 | 80 - 250 | 12.5 , 15 , 18 | 250 |

| 1.00 | 18 - 30 | 100 - 350 | 12.5 , 15 , 18 | 250 |

| 1.20 | 20 - 34 | 120 - 400 | 12.5 , 15 , 18 | 250 |

| 1.60 | 24 - 36 | 150 - 450 | 12.5 , 15 , 18 | 250 |

NIL

| ELEMENTS | C % | Mn % | Si % | P % | S % | Ni % | Cr % | Mo % | V % | Cu* % |

|---|---|---|---|---|---|---|---|---|---|---|

| SPECIFICATION | 0.06 - 0.15 | 1.00 - 1.50 | 0.65 - 0.85 | 0.025 MAX | 0.035 MAX | 0.15 MAX | 0.15 MAX | 0.15 MAX | 0.03 MAX | 0.50 MAX |

| TYPICAL VALUE | 0.07 | 1.09 | 0.70 | 0.010 | 0.010 | 0.010 | 0.010 | 0.010 | 0.010 | 0.20 |

| SHIELDING GAS | TENSILE STRENGTH, Mpa |

Yield Strength at 0.2 % offset >Mpa |

ELONGATION % | CVN Impact at -20⁰ C , J | |

|---|---|---|---|---|---|

| SPECIFICATION | 100 % CO2 | 480 min | 400 min | 22 min | 27 min |

| AR + (5 - 20)% CO2 | 530 - 680 | 460 min | 22 - 35 | 27 min |

| SIZE ( mm ) | VOLTAGE, V | AMPS | WEIGHT (kg) / SPOOL | MIG/ MAG DRUM, kg |

|---|---|---|---|---|

| 0.80 | 17 - 27 | 80 - 250 | 12.5 , 15 , 18 | 250 |

| 1.00 | 18 - 30 | 100 - 350 | 12.5 , 15 , 18 | 250 |

| 1.20 | 20 - 34 | 120 - 400 | 12.5 , 15 , 18 | 250 |

| 1.60 | 24 - 36 | 150 - 450 | 12.5 , 15 , 18 | 250 |

NIL

| ELEMENTS | C % | Mn % | Si % | P % | S % | Ni % | Cr % | Mo % | V % | Cu* % |

|---|---|---|---|---|---|---|---|---|---|---|

| SPECIFICATION | 0.06 - 0.15 | 1.40 - 1.85 | 0.80 - 1.15 | 0.025 MAX | 0.035 MAX | 0.15 MAX | 0.15 MAX | 0.15 MAX | 0.03 MAX | 0.50 MAX |

| TYPICAL VALUE | 0.07 | 1.45 | 0.85 | 0.016 | 0.010 | 0.010 | 0.016 | 0.010 | 0.010 | 0.20 |

* INCLUDING FINISHED COPPER COATING %

| PROPERTIES | SHIELDING GAS | TENSILE STRENGTH, Mpa |

Yield Strength at 0.2 % offset >Mpa |

ELONGATION % | CVN Impact at -30⁰ C , J |

|---|---|---|---|---|---|

| SPECIFICATION | 100 % CO2 | 480 min | 400 min | 22 min | 27 min |

| SIZE ( mm ) | VOLTAGE, V | AMPS | WEIGHT (kg) / SPOOL | MIG/ MAG DRUM, kg |

|---|---|---|---|---|

| 0.80 | 17 - 27 | 80 - 250 | 12.5 , 15 , 18 | 250 |

| 1.00 | 18 - 30 | 100 - 350 | 12.5 , 15 , 18 | 250 |

| 1.20 | 20 - 34 | 120 - 400 | 12.5 , 15 , 18 | 250 |

| 1.60 | 24 - 36 | 150 - 450 | 12.5 , 15 , 18 | 250 |

We’re about innovation, performance and delivering the best for our customers with every product we offer.