Ni-Fe Type Electrode for Repair and Welding of Cast Iron

AWS / SFA 5.15 – E NiFe-Cl

General Reclamation and Cast Iron Repair Electrode

AWS / SFA 5.15 ESt

Welding electrodes are consumable metal products that are used in the process of welding. They provide a pool of molten metal to be used for welding.

Welding electrodes are used to create heat and energy to weld two or more pieces of metal together.

The metal pieces come in various shapes and sizes depending on what they will be used for. The diameter of the rod is determined by the thickness of the metal to be welded and the length is determined by how long you want your weld to be.

To create filler welds, arc welding electrodes made from cast iron are used. The electrode consists of metal core wire coated with flux.

The wire core produces an electric arc that melts the workpiece and the electrode, to give the molten metal with slag coverage. The slag protects the weld metal from atmospheric contamination.

Nickel alloy electrodes are the most commonly used electrodes to weld cast iron. Nickel-iron welds are stronger due to their lower coefficient of thermal expansion, which reduces welding stresses and enhances crack resistance.

Cast Iron Welding Electrodes are used for a variety of applications. These electrodes provide a smooth, durable, and economical weld that has good slag qualities.

The electrode provides a better joint and reduces the risk of having an inadequate weld or seam separation.

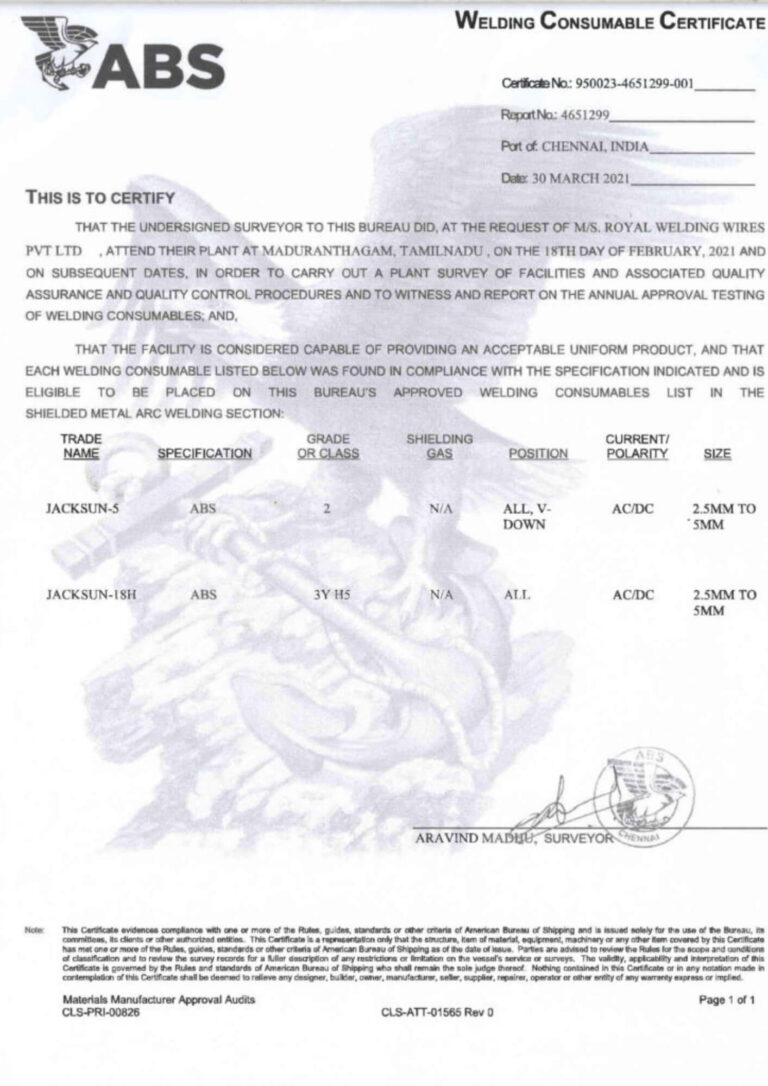

JACKSUN CAST (M) is an innovative electrode solution for repairing and welding Cast Iron Welding Electrodes.

The CAST ALLOY is machineable and it features a dense, soft, and ductile weld with adequate strength for repairing cracks, holes, and general repairs.

With excellent colour matching to cast iron and no need for preheating for large, heavy castings, JACKSUN CAST (M) is the perfect product to have on hand in the workshop!

JACKSON CAST (N M) features an improved crack resistivity, strong and rigid joints between cast iron parts, excellent colour match to Cast Iron Welding Electrodes, preheating is recommended for heavy and complicated sections, and versatile.

| ELEMENTS | C % | Ni % | Fe % | Mn % | Si % | S % | Cu % | Al % |

|---|---|---|---|---|---|---|---|---|

| SPECIFICATION | 2.0 Max | 45.0 - 60.0 | Rem. | 2.5 Max | 4.0 Max | 0.03 Max | 2.5 Max | 1.0 Max |

| TYPICAL VALUE | 1.10 | 52 | Rem. | 1.20 | 1.50 | 0.02 | 0.50 | 0.03 |

| PROPERTIES | TENSILE STRENGTH, Mpa |

Yield Strength at 0.2 % offset >Mpa |

ELONGATION % | HARDNESS - BHN |

|---|---|---|---|---|

| SPECIFICATION | 400 - 579 | 296 - 434 | 6 to 18 | 165 - 218 |

| TYPICAL VALUE | 490 | 395 | 12 | 195 |

| SIZE X LENGTH | AMPS | WEIGHT (kg) / POCKET | CARTON / POCKET |

|---|---|---|---|

| 2.50 X 350 | 50 - 80 | 2 | 8 |

| 3.15 X 350 | 70 - 110 | 2 | 8 |

| 4.00 X 450 | 100 - 140 | 2 | 8 |

| 5.00 X 450 | 130 - 180 | 2 | 8 |

NIL

GRADES: AWS / SFA 5.15 Est

| ELEMENTS | C % | Mn % | Si % | P % | S % | Fe % |

|---|---|---|---|---|---|---|

| SPECIFICATION | 0.15 MAX | 0.60 MAX | 0.15 MAX | 0.04 MAX | 0.04 MAX | Rem. |

| TYPICAL VALUE | 0.09 | 0.30 | 0.10 | 0.010 | 0.010 | Rem. |

HARDNESS - BHN ( 3 LAYER ) = 150 - 190

| SIZE X LENGTH | AMPS | WEIGHT (kg) / POCKET | CARTON / POCKET |

|---|---|---|---|

| 3.15 X 350 | 55 - 75 | 2 | 8 |

| 4.00 X 450 | 100 - 140 | 2 | 8 |

NIL

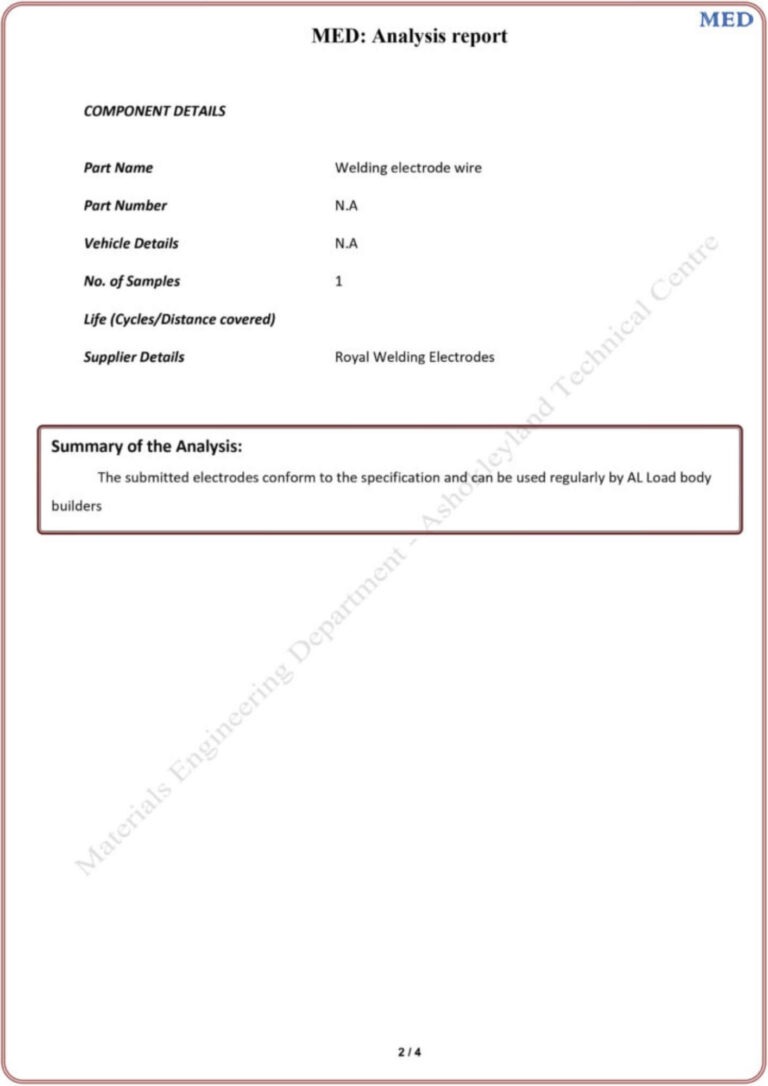

We’re about innovation, performance and delivering the best for our customers with every product we offer.