Many different welding electrodes are available, each with its unique characteristics and capabilities.

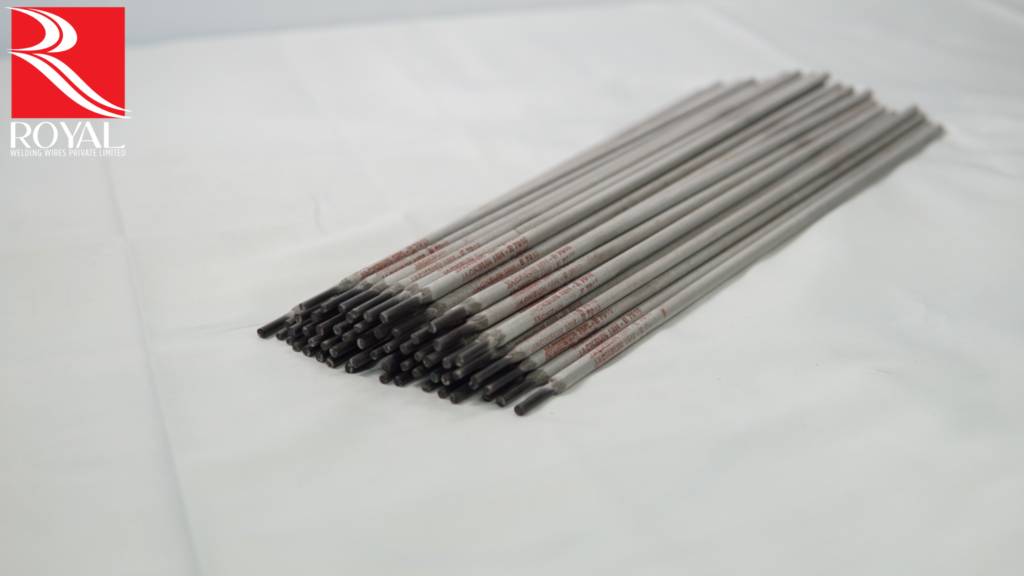

Cast iron electrodes are a type of welding electrode specifically designed for welding cast iron and other heavy-duty materials.

In this article, we will explore the benefits of using cast iron electrodes for welding, including their ability to provide increased weld strength and durability, improved conductivity and arc stability, compatibility with a wide range of base materials, and much more.

Whether you are a professional welder or a DIY enthusiast, understanding the benefits of cast iron electrodes can help you make informed decisions about the best electrodes for your welding projects.

Increased weld strength and durability:

One of the main benefits of using cast iron electrodes for welding is their ability to provide increased weld strength and durability. Cast iron is a solid and rigid material resistant to wear and corrosion. Using cast iron electrodes for welding helps maintain these properties in the welded joint.

This makes them ideal for applications where the welded components will be subjected to heavy loads or harsh environments.

Improved conductivity and arc stability:

Another benefit of cast iron electrodes is their improved conductivity and arc stability.

Cast iron electrodes are highly conductive, which allows for a smoother and more stable arc during the welding process. This can help improve the weld’s quality and reduce the risk of defects or imperfections.

Compatibility with a wide range of base materials:

Cast iron electrodes are also compatible with many base materials, including carbon steel, low-alloy steel, and other ferrous alloys.

This makes them a versatile choice for welding various materials and can help reduce the number of different electrodes that need to be kept on hand for different welding applications.

Ease of use and versatility in welding applications:

In addition to their strength and conductivity, cast iron electrodes are also easy to use and versatile in welding applications.

They can be used with various welding processes, including shielded metal arc welding (SMAW) and flux-cored arc welding (FCAW). They are suitable for use in both manual and automated welding systems.

Cost-effectiveness and availability:

Another benefit of cast iron electrodes is their cost-effectiveness and availability. Cast iron is a relatively inexpensive material, and cast iron electrodes are generally more affordable than other types of electrodes.

They are also widely available and can be easily purchased from welding supply stores or online.

Resistance to corrosion and wear:

In addition to their strength and affordability, cast iron electrodes are also resistant to corrosion and wear. This makes them ideal for applications where the welded components will be exposed to harsh environments or corrosive materials.

Improved weld appearance and finish:

Another benefit of using cast iron electrodes is the improved appearance and finish of the weld. Cast iron electrodes produce a smooth and consistent weld bead that has a clean and professional appearance.

This can be especially important in applications where the welded components will be visible or subject to scrutiny.

Join the welding revolution and upgrade to the power of cast iron electrodes! Get stronger, smoother and more efficient welds today. Click now to learn more about the benefits of cast iron welding electrodes!

Superior performance in high-temperature welding environments:

Cast iron electrodes are also well-suited for use in high-temperature welding environments.

They have a high melting point and are resistant to thermal shock, which makes them ideal for use in applications where the welded components will be subjected to high temperatures or rapid temperature changes.

Increased productivity and efficiency in welding operations:

Using cast iron welding electrodes can help increase productivity and efficiency.

They are easy to use and produce high-quality welds, which can help to reduce the amount of time and resources required to complete a welding project.

Enhanced safety in welding applications:

Using cast iron welding electrodes can also enhance safety. They are easy to handle and produce a stable and controllable arc, which can help to reduce the risk of accidents or injuries during the welding process.

FAQ (Frequently Asked Questions)

Q: Are cast iron electrodes resistant to corrosion and wear?

Q: Do cast iron electrodes produce a high-quality weld appearance and finish?

Q: Are cast iron electrodes suitable for use in high-temperature welding environments?

Q: Do cast iron electrodes require special storage or handling?

Conclusion

In conclusion, using cast iron electrodes for welding has several benefits. These electrodes offer excellent resistance to abrasion and impact, making them ideal for high wear and tear applications.

They also have a low melting point, which allows for easy and efficient welding of cast iron.

In addition, cast iron electrodes produce solid and durable welds resistant to cracking and breakage. Overall, using cast iron electrodes can significantly improve the quality and durability of welds in various applications.

Learn More

How to Choose the Right Amperage for Welding Cast Iron Electrodes?