Does flux core wire go bad? Our article will help determine whether it’s time to replace your welding wire.

Introduction

Flux core wire is used in some electrical applications and can last a long time before it needs to be replaced.

However, flux core wire can only go right if maintained correctly. If the wire becomes exposed to water or other contaminants, it can start to break down and eventually fail.

What is Flux Core Wire?

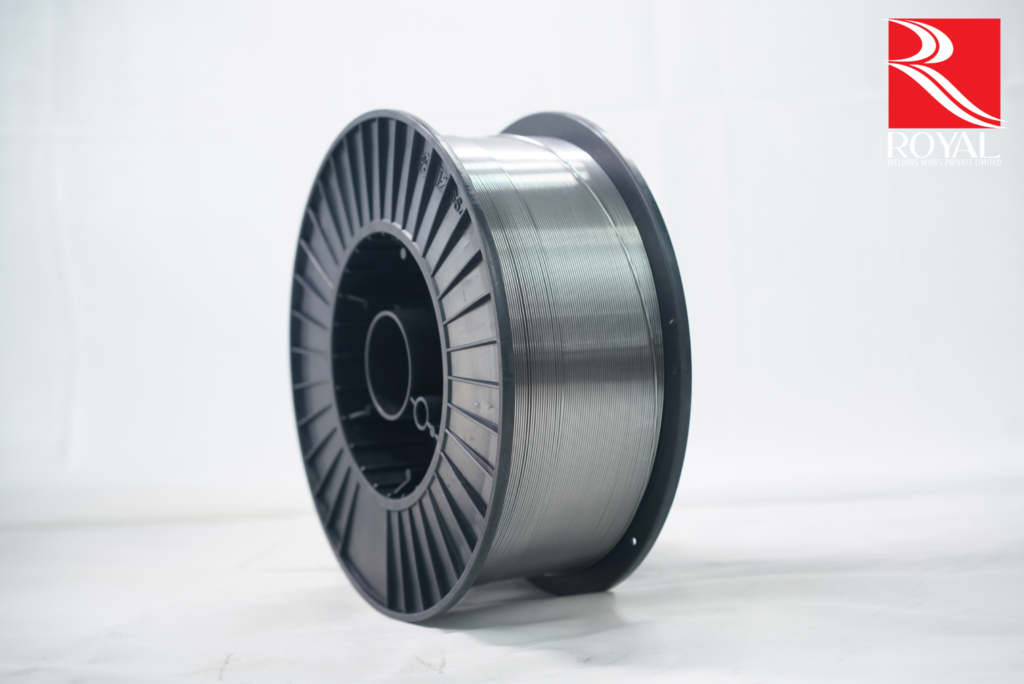

Flux core wire is a type of electrical wire used in electrical wiring. It has a thin, circular metal sheath around a core of solidified molten metal.

The flux core wire is wrapped in the sheath so the molten metal can flow freely. This makes the flux core wire an excellent choice for high-voltage applications, such as power transmission and electric motors.

The main disadvantage of flux core wire is that it can easily rust if not correctly cared for.

It is essential to keep the wires dry and free of dust and other debris and avoid touching them with your hands or tools when wet.

Does Flux Core Wire Go Bad?

Flux core wire is wiring that uses a flux material to help keep the current flowing through the wire. Flux core wires are often used in electrical applications with high currents, such as in electric motors.

Flux core wire can last many years without any problems, but it has a limited life span. Over time, the flux material can break down, leading to erratic behavior in the wiring and eventual failure. If you notice any changes in your flux core wire’s behavior or if it starts to fail, you should replace it as soon as possible.

What are the dangers of flux core wire?

Flux core wire is used in electric generators and other high-power applications. It is made of a heavy, twisted metal cord coated with phosphor.

When an electric current is passed through the wire, the phosphor glow causes heat and light, which creates electricity.

However, flux core wire can also create dangerous sparks if it comes into contact with another object.

This can cause fires and injuries. Additionally, flux core wire is susceptible to electronic shock if it comes into contact with electrical equipment. This can cause serious injuries or even death.

Don’t Risk Your Welding Quality – Ensure Your Flux Core Wire is Fresh and Reliable with Our High-Quality Option Today!

How to test if the flux core wire is terrible?

If you are experiencing any problems with your flux core wire, it is essential to test it to see if it is terrible. You can take a few simple steps to try whether or not your wire is defective.

The first step is to determine the source of the problem. If you are experiencing intermittent failures, it may be that the wire is terrible, but the loss is due to a problem with the power supply or the circuit itself. In this case, testing will only confirm that the wire is defective and not help resolve the issue.

If you are experiencing continuous failures, however, it may be that the wire is wrong and needs to be replaced. To test whether or not your wire is terrible, you will need to measure its resistance. The easiest way to do this is by using an Ohmmeter.

Be sure to use a low ohm setting to avoid damaging your wire. If your resistance reads high, your wire may be defective and should be replaced.

What are the benefits of using flux core wire?

Flux core wire is a type of wire made up of several smaller wires twisted together.

This type of wire is often used in electrical wiring because it has a high resistance and can conduct electricity well. Some benefits of using flux core wire include the following:

- It has a high resistance, meaning it can conduct electricity well

- It is often used in electrical wiring because it has a high resistance and can conduct electricity very well

- It is easy to work with and can be cut easily

Why is flux core wire so crucial for electronic devices?

Flux core wire is a type of wire that is used in electronic devices because it has high electrical and thermal conductivity.

This makes it a good choice for wiring devices that need to transfer a lot of power and heat, such as processors and antennas.

One downside to flux core wire is that it can become damaged over time. This happens when the wire becomes exposed to moisture or other chemicals, which can cause oxidation and degradation of the insulation.

In extreme cases, this can lead to insulation breakdown and dangerous shorts in the circuitry.

Can I use flux core wire for commercial purposes?

Flux core wire is a welding wire with a thin copper conductor. It is often used for welding in industrial and commercial settings because of its high electrical conductivity.

Because flux core wire is so thin, it can easily break if subjected to excessive force or tension.

If you’re using flux core wire for commercial purposes, it’s essential to be aware of its risks. If your flux core wire breaks, it could create sparks that could ignite nearby materials.

This could lead to severe injuries or even death. So be sure to use flux core wire responsibly and keep an eye on it throughout the welding process.

Conclusion

In conclusion, flux core wire can last a long time before it needs to be replaced, but it can also go wrong if it needs to be maintained correctly. If you notice any changes in your wiring’s behavior or if it starts to fail, you should replace it as soon as possible.