HIGH-PERFORMANCE SAW FLUX : SFA GRADE 1 AND SFA GRADE 2 EL 8,

EM12K, and EH12K steel grades.

Submerged arc welding is a process of welding that uses an electric arc between the consumable wire and the base metal blanketed with granular flux. SAW is a process for joining metals. It is used extensively in the ship-building industry.

The S.A.W process was developed in the early 1900s and became popular in the 1940s. The process is used to weld different types of metals like steel, stainless steel, aluminium, copper, brass, nickel and other alloys.

The process has been adopted by many industries because it provides high quality welds with less distortion than other processes like gas metal arc welding or shielded metal arc welding. It is also more economical than other processes because it can be automated and requires less labor than manual welding methods.

The S.A.W process has many benefits over other welding processes, such as being faster and more economical than gas metal arc welding. It also produces less fumes and slag. The downside to this process is that it requires more skill from the welder than other processes.

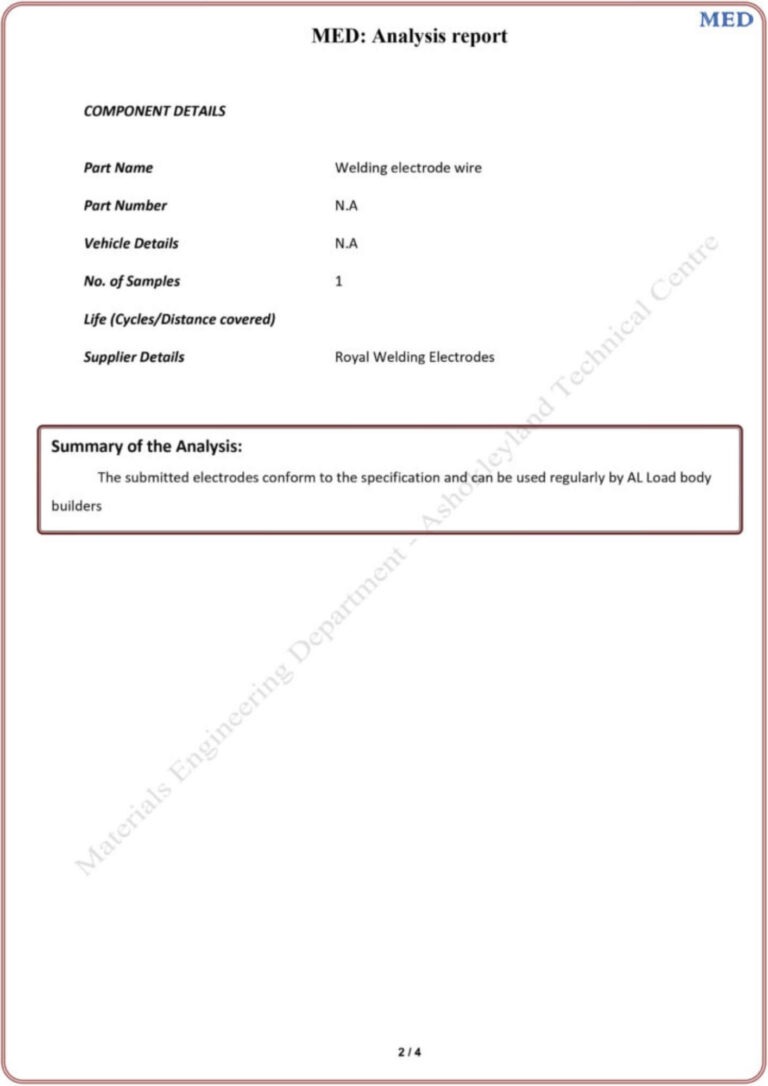

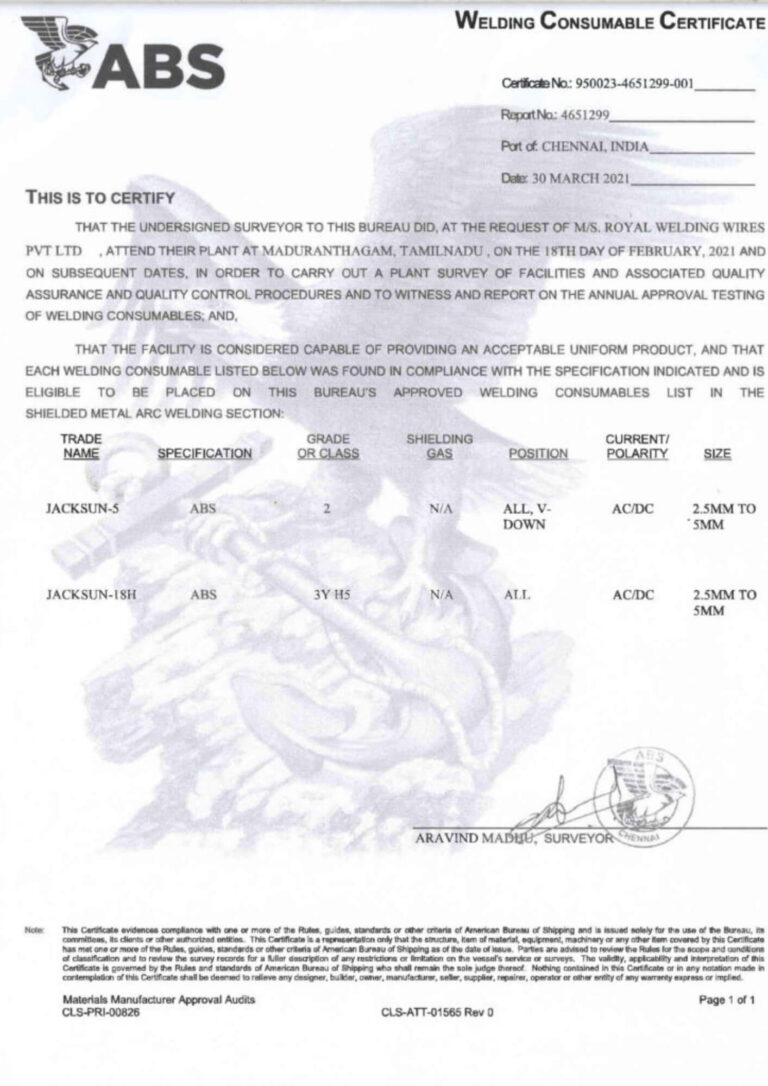

JACKSUN S.A.W Flux has been developed to high quality standards for the most demanding welding applications. It is chosen by engineers, designers and welders around the world due to its excellent quality and competitive price.

Our flux has been sintered and agglomerated. Our agglomerated fluxes are uniform in composition and provide superior performance compared to conventional fluxes.

With a high percentage of fluoride, Jacksun S.A.W Flux protects from oxidation and sulfidation while narrow gap welding and butt welding on numerous metals, including stainless steel and low alloy steel.

JACKSUN S.A.W FLUX provides you with everything you need for submerged arc welding – from lining up to multi-pass welding.

All of our flux formulations undergo rigorous testing before being packaged and shipped to you. It’s all covered by our customer service guarantee.

| ELEMENTS | Sio₂ % + TiO₂ % | Al₂O₃ % + MnO% | CaO % + MgO% | CaF₂% | H₂O % |

|---|---|---|---|---|---|

| JACKSUN SFA GRADE 1 | 30 | 55 | 5 | 5 | < 0.5 |

| JACKSUN SFA GRADE 2 | 20 | 35 | 25 | 15 | < 0.5 |

| ELEMENTS | C % | Mn % | Si % | P % | S % | Cu* % |

|---|---|---|---|---|---|---|

| EL 8 | 0.10 MAX | 0.25 - 0.60 | 0.070 | 0.030 | 0.030 | 0.35 |

| EM12K | 0.05- 0.15 | 0.80 - 1.25 | 0.10 - 0.35 | 0.030 | 0.030 | 0.35 |

| EH12K | 0.06- 0.15 | 1.50 - 2.00 | 0.25 - 0.65 | 0.025 | 0.025 | 0.35 |

| WITH WIRE | CONDITION | UTS , Mpa | YS, Mpa | EL % | WITH WIRE CVN IMPACT AT ( J ) | |

|---|---|---|---|---|---|---|

| PRODUCT NAME | SFA GRADE 1 & 2 | SFA GRADE 1 & 2 | SFA GRADE 1 & 2 | SFA GRADE 1 & 2 | SFA GRADE 1 | SFA GRADE 2 |

| JACKSUN EL8 | AS WELD | 480 - 530 | 410 - 490 | 25 - 27 | 27 min ( 0⁰ C ) | 27 min ( 0⁰ C ) |

| JACKSUN EM12K | AS WELD | 480 - 570 | 470 - 490 | 25 - 27 | 27 min ( 0⁰ C ) | 27 min ( -20⁰ C ) |

| JACKSUN EH12K | POST WELD | 480 - 660 | 400 min | 24 | 27 min ( -30⁰ C ) | 27 min ( -50⁰ C ) |

We’re about innovation, performance and delivering the best for our customers with every product we offer.